The day has come. The long-awaited moment draws nigh. It is time to unite the disparate components of R2-D2 (the ones we have, anyways) for the first time.

Yes, it is true: one year after we built R2’s frame, we are finally ready to attach his legs as a test. Two months ago we finished building the first leg, and we just recently got back around to it and finished the second leg. (They have no skins or decorative pieces, but that will come later.)

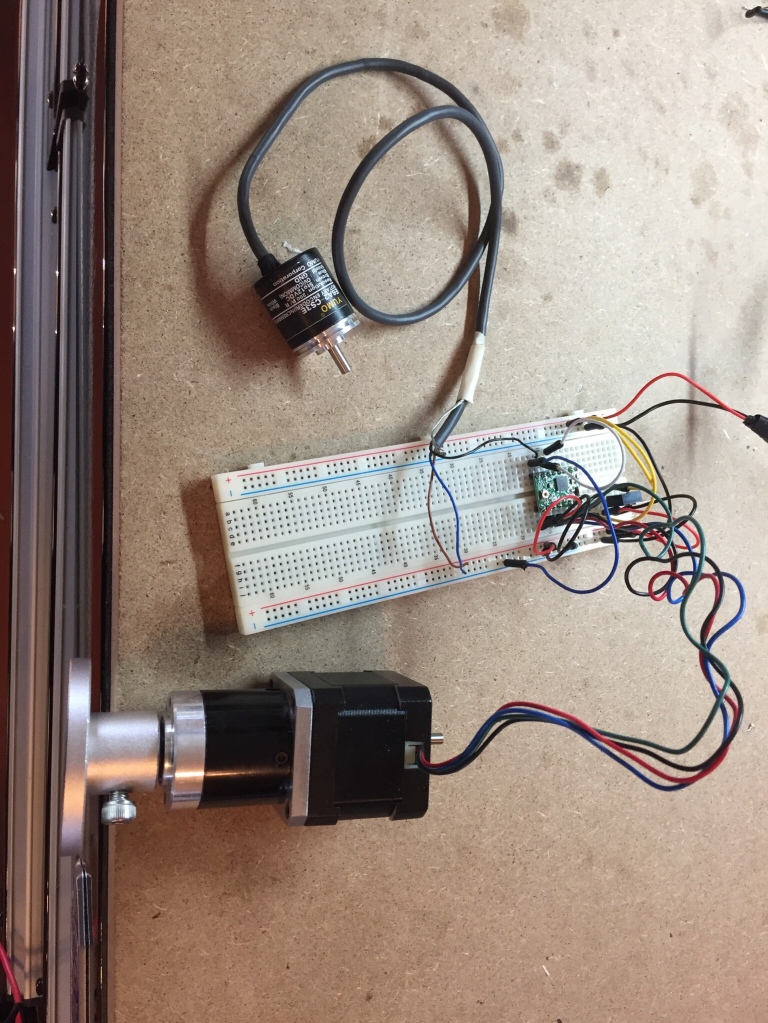

First, we experimented with one of the stepper motors that is going to control the shoulders and ankles. We hooked it up to a little stepper motor controller chip, and we also attached an encoder. When we turn the encoder, the motor steps.

Finally, it was time. We pulled the frame out of the closet and carried it to the workroom. It would have been dramatic if we could have simply attached the legs then and there, but of course there was more to it than that. We had a problem; you see, R2’s body is round, and we needed to make sure that we got everything square. The two rectangular pieces that we had hoped were completely square weren’t, so we had to figure out a way to get some straight lines. After probably an hour of measuring, marking, and clamping, we found what we needed.

Now, the legs are attached to the body via a six-sided axle that runs through the center of R2’s body. There are bearings in the side plates on each side of the body that this axle runs through, and then it terminates in the shoulder. The axle will be turned by a stepper motor inside the body.

We needed to drill the holes for the bearings in the side plates. We double-checked everything and procrastinated as long as we could, but eventually we just had to do it. We pulled out the big drill and got to it.

When the wood shavings cleared, we knew we had done an act that could never be undone, and that would have dire consequences if it was done wrong. Fortunately, it was all good. The bearings snapped into the holes, the axle slid through the bearings, and the legs slid onto the axle. We took a step back and admired our work. “Now,” we said, “this is really starting to look like R2-D2.”

Indeed it does. Two gleaming aluminum legs hang from the classic cylindrical body, bringing up memories of R2’s quirky personality and electronic chirps. All that is missing is the feet (mostly done but not attached), the plastic shell, the dome, the skins, the brain… well, still quite a bit, but, hey, it looks pretty good, and we know it works so far, too.

2017- A Recap

2017 has been an eventful year. Since starting the design in November 2016 and the build in December, we’ve gotten a fair amount of work done and learned a lot, too. Here’s a timeline of our progress so far:

- December 2016: Built the frame and the first motor control circuit

- March-April 2017: Constructed first foot and built circuit board.

- May: Worked on programming the first foot.

- June: Got the first foot drivable, started the second foot.

- July: Designed PCB for the feet.

- August: Finished PCB, added PID motor controls to the first foot.

- October: Built the first leg and most of the second.

- December: Finished the second leg and mounted the legs on the body for the first time.